Lift trucks are an essential part of many workplaces. They are used to move heavy loads, lift pallets, and transport goods. However, they can also be dangerous if not used correctly. Unfortunately, lift truck accidents are all too common, and they can result in serious injuries or even fatalities.

So, what is the number one cause of lift truck accidents? Understanding the answer to this question could save lives. In this article, we will explore the most common causes of lift truck accidents and provide tips on how to prevent them. Let’s dive in!

What Is the Number One Cause of Lift Truck Accidents?

Lift trucks, also known as forklifts, are used in various industries to move heavy loads from one place to another. They play a vital role in warehouses, construction sites, and manufacturing plants. However, they can also be dangerous if not operated safely. In fact, lift truck accidents are one of the leading causes of workplace injuries and fatalities. In this article, we will discuss the number one cause of lift truck accidents and how to prevent them.

Lack of Training

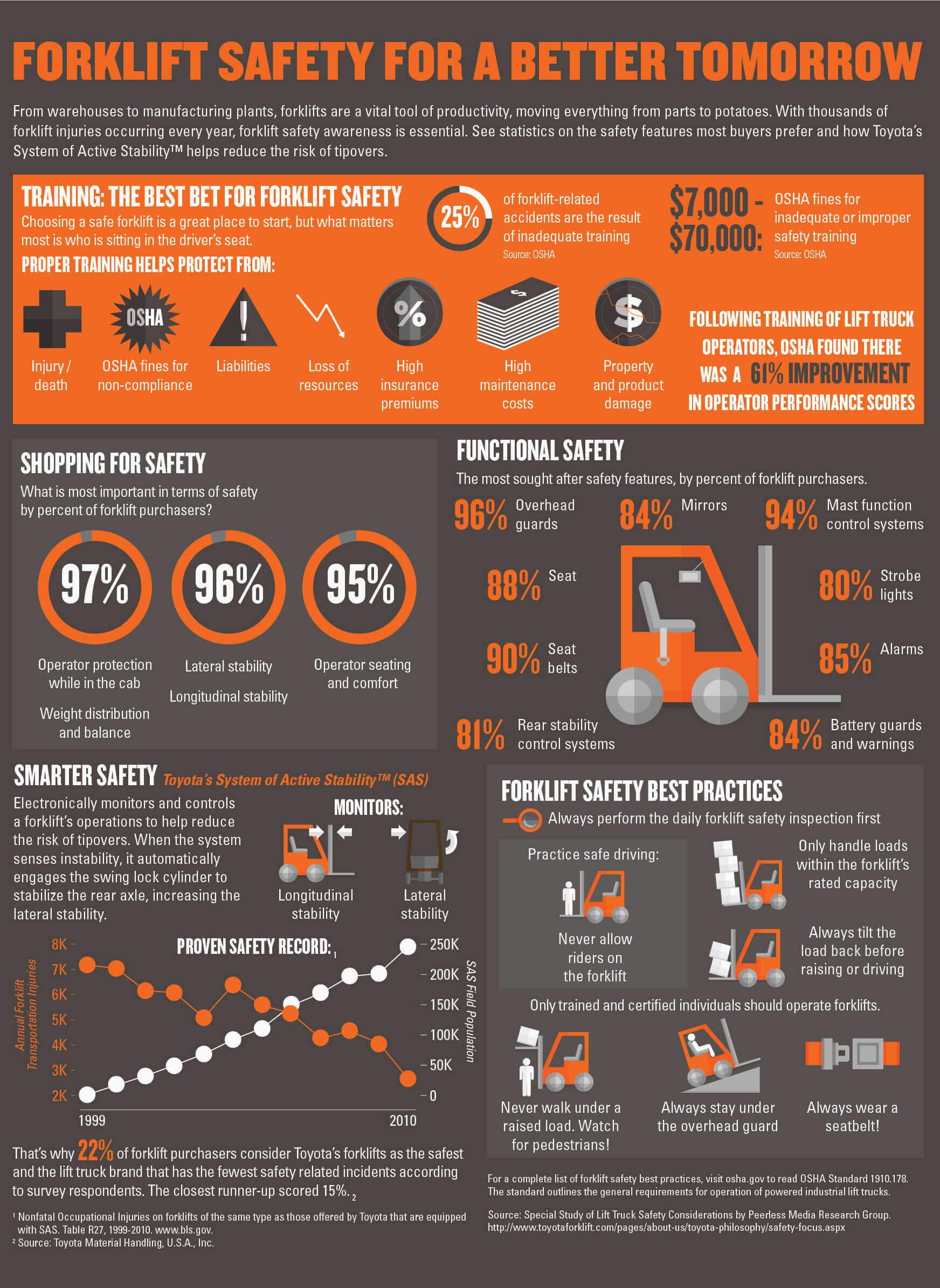

One of the main reasons for lift truck accidents is the lack of proper training. Operating a forklift requires specific skills and knowledge that cannot be acquired without training. Many accidents occur because operators do not understand the capabilities and limitations of the equipment or the safety procedures that must be followed.

Moreover, some operators may become complacent and overlook hazards after prolonged use. This can lead to accidents caused by negligence, such as driving too fast, carrying loads that are too heavy, or not paying attention to surroundings.

To prevent accidents caused by the lack of training, employers must provide comprehensive training sessions for all operators. The training should cover the safe operation of forklifts, the potential hazards in the workplace, and the use of personal protective equipment. Operators should also be required to take refresher courses to ensure that their skills and knowledge remain up-to-date.

Improper Maintenance

Another significant cause of lift truck accidents is improper maintenance. Lift trucks are complex machines that require regular maintenance to function correctly. A poorly maintained forklift can malfunction, leading to accidents that may result in serious injuries or fatalities.

Regular inspections and maintenance should be performed on forklifts to ensure that they are in good working condition. Operators should also be trained to identify potential problems and report them to maintenance personnel immediately.

Overloading

Overloading is another significant cause of lift truck accidents. Overloading can cause the forklift to become unstable, leading to tip-over accidents that can be fatal. Overloading can also cause the forklift’s braking and steering systems to fail, making it difficult to control the machine.

To avoid accidents caused by overloading, operators should be trained to check the load capacity of the forklift before lifting any loads. The load capacity should never be exceeded, and the load should be distributed evenly to ensure stability.

Improper Pedestrian Management

Another cause of lift truck accidents is improper pedestrian management. Pedestrians and lift trucks often share the same workspace, which can lead to accidents if not managed correctly. Pedestrians must be aware of the forklift’s presence and stay clear of the operating area.

To prevent accidents caused by improper pedestrian management, employers should implement strict guidelines that separate pedestrian and lift truck traffic. Pedestrian walkways should be designated, and forklifts should be prohibited from entering these areas.

Lack of Communication

Lack of communication is another significant cause of lift truck accidents. Communication is critical in any workplace, but it is especially crucial when working with lift trucks. Operators must communicate with each other and with pedestrians to ensure that everyone is aware of the forklift’s movements.

To prevent accidents caused by a lack of communication, employers should implement a communication system that allows operators and pedestrians to communicate effectively. This can be done through the use of hand signals, radios, or other communication devices.

Improper Use of Attachments

Lift truck attachments can be useful in specific applications, but they can also be dangerous if not used correctly. Improper use of attachments can cause the forklift to become unbalanced, leading to tip-over accidents or load spills.

To avoid accidents caused by improper use of attachments, operators should receive training on the proper use of attachments. They should also be aware of the forklift’s load capacity when using attachments and should never exceed it.

Improper Parking and Storage

Improper parking and storage of forklifts can also lead to accidents. Forklifts should be parked in designated areas that are clear of pedestrian traffic and other obstacles. They should also be stored in a safe and secure location when not in use.

To prevent accidents caused by improper parking and storage, employers should designate specific areas for parking and storage. Operators should be trained to park the forklifts correctly, and the areas should be clearly marked to prevent confusion.

Lack of Personal Protective Equipment

Operators of lift trucks should wear personal protective equipment (PPE) to safeguard themselves from potential injury. PPE includes a hard hat, safety glasses, and high-visibility clothing. Not wearing PPE can lead to injuries caused by falling objects, collisions, or other accidents.

To prevent accidents caused by the lack of PPE, employers should provide the necessary protective equipment to operators and enforce its use. Operators should also be trained on the proper use and maintenance of PPE.

Fatigue and Distractions

Fatigue and distractions can also lead to lift truck accidents. Operators who are tired or distracted may not be able to react quickly to potential hazards, increasing the risk of accidents.

To avoid accidents caused by fatigue and distractions, employers should implement a schedule that allows for adequate rest breaks, and operators should be trained to identify the signs of fatigue. Operators should also be prohibited from using mobile devices or other distractions while operating the forklift.

Conclusion

In conclusion, lift truck accidents can cause serious injuries or fatalities in the workplace. The number one cause of lift truck accidents is the lack of proper training. Employers should provide comprehensive training sessions for all operators, implement maintenance schedules, and enforce safety guidelines to prevent accidents. By following these guidelines, employers can ensure a safe and healthy workplace for their employees.

Frequently Asked Questions

How can I prevent lift truck accidents?

The best way to prevent lift truck accidents is by ensuring that operators are properly trained and certified. Employers should provide regular training and enforce safety protocols to minimize risks. It is also important to perform regular maintenance checks on lift trucks to ensure they are in good working condition. Operators should also be required to wear appropriate safety gear, such as helmets and reflective vests.

Additionally, it is important to establish clear rules and guidelines for lift truck operation. This includes setting speed limits, designating specific areas for loading and unloading, and ensuring that there are no obstacles in the path of the lift truck. By taking these steps, lift truck accidents can be significantly reduced.

What are some common causes of lift truck accidents?

Some common causes of lift truck accidents include operator error, equipment malfunctions, and improper maintenance. Operator error can occur when drivers are not properly trained or when they engage in risky behaviors, such as speeding or taking sharp turns. Equipment malfunctions can occur due to lack of maintenance or faulty parts. Improper maintenance can also lead to accidents, as worn or damaged parts can cause the lift truck to malfunction.

Other causes of lift truck accidents include poor visibility, obstacles in the path of the lift truck, and improper loading or unloading procedures. By identifying these common causes, employers can take steps to prevent accidents from occurring.

What are some best practices for lift truck operators?

Lift truck operators should follow established safety protocols at all times. This includes wearing appropriate safety gear, such as helmets and reflective vests. Operators should also be properly trained and certified to operate the specific type of lift truck they will be using. It is important to follow speed limits and be aware of potential hazards, such as obstacles in the path of the lift truck or poor visibility.

Other best practices for lift truck operators include performing regular maintenance checks on the lift truck, reporting any issues or malfunctions immediately, and following proper loading and unloading procedures. By following these practices, lift truck operators can help prevent accidents and keep themselves and others safe.

Why is proper maintenance important for lift trucks?

Proper maintenance is essential for lift trucks to operate safely and efficiently. Regular maintenance checks can help identify and fix any issues before they become serious problems. This can help prevent equipment malfunctions and reduce the risk of accidents. Maintenance checks should include inspecting the lift truck’s brakes, tires, steering, and other critical components. Any worn or damaged parts should be replaced immediately to ensure the lift truck is in good working condition.

In addition to reducing the risk of accidents, proper maintenance can also help extend the lifespan of the lift truck. By identifying and fixing issues early, employers can avoid costly repairs and replacement of the lift truck.

What are the consequences of lift truck accidents?

Lift truck accidents can have serious consequences, including injuries and fatalities. Accidents can also result in damage to equipment and property, which can be costly to repair or replace. In addition to these immediate consequences, lift truck accidents can also result in lost productivity and increased insurance costs for employers.

For lift truck operators, accidents can result in serious injuries, such as broken bones, head injuries, and spinal cord injuries. These injuries can be life-changing and may require extensive medical treatment and rehabilitation. In some cases, lift truck accidents can also be fatal. By taking steps to prevent accidents, employers can help protect their employees and minimize the risk of these devastating consequences.

Top 10 Forklift Accidents !

In conclusion, the number one cause of lift truck accidents is operator error. This can include a lack of training and experience, as well as distractions while operating the vehicle. It is crucial for operators to receive proper training and for companies to enforce safety protocols to prevent accidents.

Additionally, maintenance and upkeep of lift trucks are also important factors in preventing accidents. Regular inspections and repairs can ensure that the vehicle is functioning properly, reducing the risk of malfunctions or breakdowns that can lead to accidents.

Ultimately, preventing lift truck accidents requires a combination of proper training, safety protocols, and maintenance. By prioritizing safety and taking proactive measures, companies can ensure that their workers are protected and that their operations run smoothly.

Injured? Contact us for a free consultation.